Hydraulics and Lubrication

Hydraulic filters are critical to extending the life span of your system. Contamination in the lubrication or hydraulics oils result in over half of equipment failure. It is critical to use the correct filters and replace them on a preventative maintenance schedule. Cobetter can provide comprehensive oil analysis which can help identify the correct oil purification equipment required.

| Product | Membrane | Main Construction Material | Availability Configuration | Applications | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Glass Fiber | Cellulose | Plastic | PP | Metal | Cartridge | Liquid | ||||

| WX Economic → | • | • | • | • | ||||||

| BAR → | • | • | • | • | ||||||

| HDP → | • | • | • | • | ||||||

| RF → | • | • | • | • | • | |||||

View Key Features & Benefits by Series | Hydraulics and Lubrication

WX Series | ||||||

|---|---|---|---|---|---|---|

| Cobbetter WX Economic Filter Cartridges use high performance, ultra-fine glass fiber media which results in high filtration efficiency (99.9% efficient at rated pore size, Beta Ratio (β) ≥ 1000, meeting ISO Standard 16889) and ensures the cleanliness the oil. | |||||

| Ultra-Fine Glass Filter Media | Graded pore size with coarse (upstream) to fine (downstream) distribution provides high contaminant holding capacity and extends the filter's service life 3-D structure improves flow rate and reduces pressure loss | |||||

| Coreless Filter Design | Coreless filter design reduces filter cost | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Bar Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter BAR Filter Cartridges use high performance, ultra-fine glass fiber media which results in high filtration efficiency (99.9% efficient at rated pore size, Beta Ratio (β) ≥ 1000, meeting ISO Standard 16889) and ensures oil cleanliness. | |||||

| Ultra-Fine Glass Filter Media | Graded pore size with coarse (upstream) to fine (downstream) distribution provides high contaminant holding capacity and extends the filter's service life 3-D structure improves flow rate and reduces pressure loss | |||||

| Stainless Steel Cores and End Caps | Strengthens the filter for us in high pressure and viscosity oils | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

HDP Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter HDP Filter Cartridges use high performance, ultra-fine glass fiber media which results in high filtration efficiency (99.9% efficient at rated pore size, Beta Ratio (β) ≥ 1000, meeting ISO Standard 16889) and ensures oil cleanliness. | |||||

| High Performance Ultra- Fine Glass Fiber Media | Graded pore size with coarse (upstream) to fine (downstream) distribution provides high contaminant holding capacity and extends the filter's service life 3-D structure improves flow rate and reduces pressure loss | |||||

| Stainless Steel Cores and End Caps | Strengthens the filter for us in high pressure and viscosity oils in demanding high differential pressure applications | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

RF Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter RF Filter Cartridges use high performance, ultra-fine glass fiber media which results in high filtration efficiency (99.9% efficient at rated pore size, Beta Ratio (β) ≥ 1000, meeting ISO Standard 16889) and ensures oil cleanliness. | |||||

| High Performance Ultra- Fine Glass Fiber Media | Graded pore size with coarse (upstream) to fine (downstream) distribution provides high contaminant holding capacity and extends the filter's service life 3-D structure improves flow rate and reduces pressure loss | |||||

| Stainless Steel Cores and End Caps | Strengthens the filter for use in high pressure and viscosity oils | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

High Temp / Viscosity Cartridges

For high temperature or highly viscous chemicals it is important to choose a filter strong enough to handle these conditions. The material needs to be compatible with the chemistries being used and also able to handle elevated temperatures. The three dimensional pore structure should be strong enough to not compress with high viscous chemicals being forced through the medias pore structure. A properly designed and specified filter is imperative for these types of applications.

| Product | Membrane | Main Construction Material | Availability Configuration | Applications | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Polyphenylene Sulphide (PPS) | Metal | Nylon | Plastic | Metal | Cartridge | Liquid | Gas | |||||

| PSSF Pleated SS Felt → | • | • | • | • | ||||||||

| PSSC Pleated SS Felt → | • | • | • | • | ||||||||

| CSSC Cylindrical SS Sintered Wire Cloth → | • | • | • | • | ||||||||

| SSPS Sintered Stainless Steel Powder → | • | • | • | • | • | |||||||

| TIC Titanium Metal Powder → | • | • | • | • | • | |||||||

| 150PPS Filter → | • | • | • | • | ||||||||

| PPS Filter → | • | • | • | • | ||||||||

| SuperNylon Melt Blown → | • | • | • | • | ||||||||

View Key Features & Benefits by Series | High Temp / Viscosity Cartridges

PSSF Series | ||||||

|---|---|---|---|---|---|---|

| PSSF Stainless Steel Pleated Felt Filter Cartridges are composed of stainless steel sintered felt. These filters have a large filtration area with high flow rates and low pressure drops.The unique stainless steel sintered felt is made from stainless steel fibers which have been sintered to form a high-porous depth filtration material. | |||||

All stainless steel construction | Excellent chemical compatibility High temperature resistance | |||||

Sintered specialized alloy construction | High corrosion and oxidation resistance Can be cleaned and reused | |||||

Absolute graded pore size rated media | Precision particulate retention ratings | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

PSSC Series | ||||||

|---|---|---|---|---|---|---|

| PSSC Pleated Stainless Steel Wire Cloth Filter Cartridges are composed of 316 stainless steel wire cloth. The pleated structure provides a large filtration area which results in longer service life and higher flow rates. | |||||

All stainless steelconstruction withpleated wire cloth and inside support layer | Excellent chemical compatibility High temperature and pressure resistance High corrosion and oxidation resistance Non-fiber releasing | |||||

Absolute gradedpore size rated media | Homogenous pore sizes Precision particulate retention ratings | |||||

Constructed for cleaning and reuse | Able to be cleaned and reused High pressure back-flushing available | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

CSSC Series | ||||||

|---|---|---|---|---|---|---|

| CSSC® Cylindrical Stainless Steel Sintered Wire Cloth Filters with multiple layers of 316 sintered stainless steel wire cloth result in superior strength and corrosion and thermal resistance. | |||||

100% stainless steel construction | Excellent chemical compatibility High temperature resistance | |||||

5 layers of 316 stainless steel wire cloth and reinforcing layer | Superior strength and corrosion and thermal resistance Non-fiber releasing | |||||

Homogenous pore sizes; Absolute graded pore size rated media | Precision particulate retention ratings | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

SSPS Series | ||||||

|---|---|---|---|---|---|---|

| SSPS® Sintered Powder Filter Cartridges are constructed with stainless steel powder. First shaped with pressure and then sintered under high temperature by applying unique technology and a strict manufacturing production process. Features include high mechanical strength, high temperature resistance, even pore distribution, and cleanable/reusable filters. | |||||

100% stainless steel construction | Excellent chemical compatibility High temperature resistance | |||||

Even-sintered construction | Superior strength and corrosion and thermal resistance Non-fiber releasing Narrow pore distribution with high separation efficiency Controlled shape to withstand high reverse-flow | |||||

Homogenous pore sizes; Absolute graded pore size rated media | Precision particulate retention ratings | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

TIC Titanium Metal Powder Filter Series | ||||||

|---|---|---|---|---|---|---|

| TIC® Titanium Metal Powder Filter Cartridges are composed of high-purity industrial-grade titanium powder (99.4%) with all elements sintered at high temperatures. Its features include anti-chemical corrosion, oxidation and high temperature resistance, and long service life. Designed for low viscosity liquid filtration, this filter results in good solid-liquid separation efficiency.This filter is mainly used as a chemical filter to remove ozone-depleting substance and for the removal of carbon dioxide in food, pharmaceutical, and water treatment applications. | |||||

High purity titanium construction | Anti-corrosive High temperature and oxidation resistant | |||||

Even-sintered construction | Narrow pore distribution with high separation efficiency Non-shedding Controlled shape to withstand high reverse-flow | |||||

Non-toxic, non-magnetic nature | Good fluid compatibility and cleanliness | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

150PPS Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter™ 150PPS Core-less Filter Cartridges are designed without a core for environmentally-friendly applications where high performance and low cost are paramount. These filters feature 100% Polyphenylene Sulphide (PPS) media guaranteeing excellent chemical stability, electric isolation, and thermostability. Large diameter core-less cartridges feature low differential pressure, particularly suitable for high flow filtration. | |||||

| Core-Less, Polyphenylene Sulphide (PPS) Media | Low differential pressure media with a large diameter cartridge making it suitable for high liquid flow Ideal for high flow and high temperature applications. PPS media provides excellent performance in chemical stability, electric isolation, and thermo-stability. Ideally designed to fit with 316L stainless steel core. Quick and easy installation/removal over the core which leaves the core in the filter housing. (Separate stainless steel core remains in the filter which results in a lower disposal cost and more environmentally-friendly.) | |||||

| Standard Size/ Construction | Direct replacement for other core-less products. Simple structure with easy operation and low installation and operational costs. | |||||

| Quality Assurance | Manufactured in a facility which adheres to ISO 9001 Practices. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

PPS Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter™ PPS Filter Cartridges are designed where high performance and high temperature are paramount. These filters feature Polyphenylene Sulphide (PPS) media for excellent chemical thermostability. | |||||

| Polyphenylene Sulphide (PPS) Media | Ideal for high temperature applications. PPS media provides excellent performance in chemical stability, electric isolation, and thermo-stability. Ideally designed to fit with DOE stainless steel housings. | |||||

| Quality Assurance | Manufactured in a facility which adheres to ISO 9001 Practices. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

SupaNylon Melt Blown | ||||||

|---|---|---|---|---|---|---|

| SupaNylon® Melt Blown Filters are made of 100% nylon melt-blown depth media without surfactants, binders, or adhesives. Melt-blown depth media consists of gradient pores. The cartridge is capable of efficiently capturing particles of different sizes with a great flow rate and lifetime. These cartridges have been designed for applications where polypropylene filters cannot be used. | |||||

| Melt-blown 100% nylon media with gradient pores | Provides high contaminant hold capacity and high removal efficiency at low pressure drop Long service life, high flow rate due to the different linear diameters and unique interwoven density control process. SupaNylon has a porosity far beyond that of similar products, which results in lower pressure loss across the cartridge and higher contaminant-holding capacity. Stable pore structure and high-purity filtration. Manufactured with no wetting agents, solvents, surfactants, binders, or adhesives. Wide range of filtration rates from 0.5 μm to 40 μm to meet various operation conditions. | |||||

| Quality Assurance | Manufactured in a facility which adheres to ISO 9001 Practices. | |||||

| Particle shedding | Autoclaved filter effluent meets the requirements in USP <788> for large volume parenterals. | |||||

| Cleanliness | Food Contact Declaration 2008/39/EC (2002/72/EC) | |||||

| Non-fiber release | Component materials meet the criteria for a “Non-fiberreleasing filter” as defined in 21 CFR210.3 (b) (6). | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Degassing or Injection Contactors

Degassing or Injection Contactors are designed to remove or inject gas from a liquid solution. Hollow fibers are utilized in these units to increase surface contact area. This contact area is critical for the efficiency of the units. Vacuum is used on the inside of the hollow fiber tubes to pull gas from the liquid that is flowing on the outside of the tubes, resulting in degassing the liquid. If the unit is pressurized with gas, the gas is injected/aeriated into the liquid as it flows through the units.

| Product | Membrane | Main Construction Material | Availability Configuration | Applications | ||||

|---|---|---|---|---|---|---|---|---|

| PP | Plastic | PP | Capsule | Liquid | Gas | |||

| ArrayForce → | • | • | • | • | • | • | ||

View Key Features & Benefits by Series | Degassing or Injection Contactors

ArrayForce Series | ||||||

|---|---|---|---|---|---|---|

| Cobbetter Arrayforce™ gas-liquid separation membrance contactors use hydrophobic hollow fiber membrane techology to remove dissolved gases from liquids, or to inject gases into liquids. In typical operation, liquid to be degassed flows outside the hollow fiber. At the same time, vacuum, sweep gas or a certain adsorption liquid go through inside the hollow fiber. There are a lot of micro pores on the surface of hydrophobic hollow fiber, which allow gas molecules pass through, but reject water molecules. Under the force caused by vacuum, sweep gas or adsorption liquid, the gases dissolved in liquid outside the hollow fiber moves continuously through the micropores to the inside hollow fiber, and then is taken away by vacuum, sweep gas or a certain adsorption liquid. In this way, dissolved gases in liquid are removed. | |||||

| Simple operation process | Quick start. Very short time for system stability | |||||

| No chemical dosing | No chemical elements in liquid eliminates subsequent treatment steps | |||||

| Expandable configurations | Paralle or in-series contactor configurations allow simple adjustment of gas removal or injection efficiency to match process needs | |||||

| Standard housing options | Housing flange connections are designed in accordance with international standards to allow connection to industrystandard connections | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

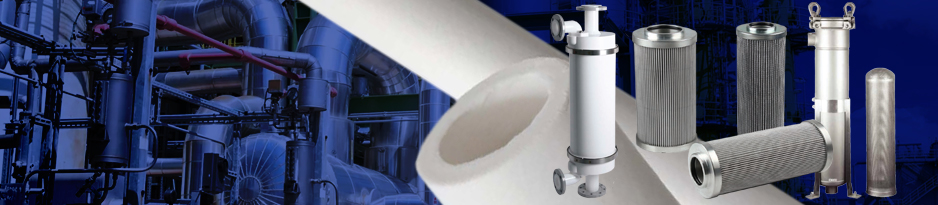

Housings

Filter housings for industrial applications come in all forms and sizes that are needed to meet chemical and flow requirements. The use of filter housings in industry is critical to producing clean products for the consumer or process that it is in. Cobetter has several industrial filter housings to choose from and they can customize to your needs.

| Product | Main Construction Material | Availability Configuration | Applications | ||

|---|---|---|---|---|---|

| Plastic | Metal | Housing | Liquid | ||

| H-CSD Lenticular Filter → | • | • | • | ||

| H-GCF Gas Filter → | • | • | • | ||

| H-GCF II Gas Filter → | • | • | • | ||

| H-CPF PTFE Lined Filter → | • | • | • | • | |

| H-CCF Single Round Industrial → | • | • | • | ||

| HCP Resin → | • | • | • | ||

| H-SICF Industrial Multi-Round → | • | • | • | ||

| H-HF150 High Flow Industrial → | • | • | • | ||

| H-FRP Filter → | • | • | • | ||

| H-MBF Bag Multi-Round (Side In/ Bottom out) → | • | • | • | ||

| H-EMBF Bag Multi-Round (Side In/ Side Out) → | • | • | • | ||

| H-LMBF Bag Multi-Round (Bottom Inlet/Outlet) → | • | • | • | ||

| H-TBF Single Round Bag (Top In, Bottom Out) → | • | • | • | ||

| H-SBF Single Round Bag (Side In, Bottom Out) → | • | • | • | ||

| H-EBF (Side In, Bottom out) → | • | • | • | ||

View Key Features & Benefits by Series | Housing

H-CSD Lenticular Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter H-CSD Lenticular Series Filter Housings are designed for use with H-CSD lenticular series filter modules. The housings are designed for sanitary requirements with well-polished surfaces to ensue no residual liquids and easy throughput for cleaning. The housings are available in 304 or 316L stainless steel, which ensures strong corrosion resistance for a wide range of applications. The bottom in/bottom out flow pattern eliminates turbulent flow, then enhancing filtration efficiency. Maximum stack height of four stacks meets high flow-rates requirements. | |||||

High flow, efficient footprint for H-CSD Lenticular modules

| Provides high purity filtration and high flow in space-saving configurations | |||||

| Quality surface finishing | With an internal Ra of 0.38 μm (15 μin.) and external Ra of 0.4 μm 16 μin), the sanitary surface finish prevents entrapment or build-up of contaminants | |||||

| Vent and drain options | Available with vent and drain options to allow easy clean and thorough drainage | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-GCF Series | ||||||

|---|---|---|---|---|---|---|

| H-GCF Gas Filter Housings are designed for air/gas filtration in biotechnology, chemical, electronic, and food & beverage industries. The housings are compatible with standard cartridges to meet the requirements of air/gas filtration. Endcap design of the housing is Code 7 (external 226 double o-ring with 2 locking tabs) which provides safe and secure sealing. Features include mechanical polishing with a Ra of 15 μin (0.3 μm), easy-to-clean, and thorough drainage which eliminates concerns about remaining liquids. Electro-polishing finish is also an available option. | |||||

| Designed for Code 7 cartridges | Provides safe and secure sealing of cartridges with 226 double o-ring and 2 locking tabs | |||||

| Quality surface finishing | With an internal Ra of 0.38 μm (15 μin.) and external Ra of 0.4 μm (16 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. All electropolishing is also available | |||||

Vent and drain options

| Available with vent and drain options to allow easy clean and thorough drainage | |||||

Standard housing options

| Housing flange connections are designed in accordance with international standards to allow connection to industry-standard connections | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-GCF II Series | ||||||

|---|---|---|---|---|---|---|

| H-GCF Gas Filter Housings are designed for medium and high-pressure air/gas filtration in biotechnology, chemical, electronic, and food & beverage industries. The housings are compatible with standard cartridges to meet the requirements of air/gas filtration. Endcap design of the housing is external 226 double o-ring with 2 locking tabs which provides safe and secure sealing. Features include mechanical polishing with a Ra of 15 μin (0.3 μm), e asy-to-clean, and thorough drainage which eliminates concerns about remaining liquids. Electro-polishing finish is also an available option. | |||||

| Designed for 226 cartridges | Provides safe and secure sealing of cartridges with 226 double o-ring and 2 locking tabs | |||||

| Quality surface finishing | With an internal Ra of 0.38 μm (15 μin.) and external Ra of 0.4 μm (16 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. All electropolishing is also available | |||||

Vent and drain options

| Available with vent and drain options to allow easy clean and thorough drainage | |||||

Standard housing options

| Housing flange connections are designed in accordance with international standards to allow connection to industry-standard connections | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-CPF PTFE Series | ||||||

|---|---|---|---|---|---|---|

| H-CPF PTFE-Lined Filter Housings are designed for use with corrosive fluids (acids & bases) in fine chemical applications. Fluid contact area is composed of PTFE or PFA which solves chemical compatibility issues with stainless steel filter housings, especially for use with aggressive acids. The housings are customizable for flow rate requirements. | |||||

| Fluoropolymer Lined Flow Path | Allows chemical compatibility with acids and bases - corrosive fluids, including Nitric Acid (conc.), Sulfuric Acid (conc.), Sodium Hydroxide (conc.), THF, TFA, and other chemicals | |||||

| Multiple Configurations to Match Flow Requirements | Available in 1, 3, 5, and 7 round configurations, and custom sizes are available. Bowl designs available for 5, 10, 20, 30, and 40- inch filter lengths. | |||||

| High Operating Temperature | With a max. operating temperature of 150°C (302°F), the housings are ideal for use in a wide range of elevated chemical flows. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-CCF Series | ||||||

|---|---|---|---|---|---|---|

| H-CCF Filter Housings feature T-line configuration which allows for easy installation into various tools and locations. The bowl is sanitary grade and has a finished polishing of Ra < 0.38μm (15 μin.) making it suitable for a variety of applications. Since the housing is a compact structure, the top of the filter housing can be supported to rigid pipe. The tri-clamp connection of the housing makes it easy to remove the bowl and replace filter elements. There is no liquid spillover during the replacement process, since the bowl can drop down after release of the tri-clamp. In addition, the drain valve located at the bottom of the filter housing allows for easy drainage. | |||||

| T-line configuration with top inlet and top outlet | T-line configuration allows tubing to be kept inline | |||||

| Tri-clamp bowl connection | No liquid spillover when replacing filter cartridges as bowl can drop down after release of clamp Design allows for safe, easy sealing of bowl to housing head | |||||

| Drain on housing bottom | Easy to drain | |||||

| Quality surface finishing | With an internal bowl Ra of 0.38μm (15 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

HCP Series | ||||||

|---|---|---|---|---|---|---|

| HCP Filter Housings are constructed of 100% natural polypropylene or PVDF without any coloring agents or chemicals. These housings provide broad chemical compatibility and are ideally suited for food & beverage, ultrapure water, and other high purity chemical applications. | |||||

100% natural polypropylene (PP) construction or PVDF | Provides cleanliness and broad chemical compatibility Low extractables - no chemicals and colorants are released during filtration process. | |||||

T-line configuration with top inlet and top outlet | inlet and top outletT-line configuration allows tubing to be kept inline | |||||

Drain on housing bottom | Easy to drain | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-SICF Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter H-SICF Filter Housings are designed for use in pre-filtration and clarification processes for beverages, drinking water, fine chemicals, pharmaceutical, and other industrial applications. Constructed of 304 or 316L stainless steel, the housing also ha s a mechanically polished surface finish and can accept filter cartridges with DOE, 222 or 226 end connections, as well as car tridges in 10”, 20”, 30”, or 40” configurations. In addition, it features a swing bolt closure at the top of the filter housing for easy access and installation. Mirror finishing and internal polishing of 0.6m Ra are ensured by mechanically polishing the filter housing 5 to 7 times. | |||||

| Designed for most common cartridges | Provides safe and secure sealing of cartridges with DOE, 222, or 226 connection. | |||||

| Quality surface finishing | With an internal Ra of 0.6 μm (24 μin.) and external Ra of 0.8 μm 32 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

| Vent and drain options | Available with vent and drain options to allow easy clean and thorough drainage. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-HF150 Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter H-HF150 Series Industrial Filter Housings are designed for use with HF150 Series Filter Cartridges and are mainly used for large fluid (liquid/water) flow rate applications, especially in water treatment, beverages, fine chemicals, pharmaceutical, and other industrial applications. Designed for large flow rates, this filter housing requires a small area for installation. It is cost efficient and easy to operate when compared to traditional filter housings and is available in 304 or 316L stainless steel, which ensures strong corrosion resistance for a wide range of applications. In addition, the H-HF150 is available in both horizontal and vertical configurations. Normally, a vertical configuration is composed of 10 round 40” filters. For flow rates over 1000 m3/h (4400 gpm), we recommend choosing a horizontal configuration with 60” HF150 filter cartridges as it satisfies large flow rate applications and is relatively easy to change. | |||||

| High flow, efficient footprint | Provides high flow in space-saving configurations | |||||

| Quality surface finishing | With an internal Ra of 0.6 μm (24 μin.) and external Ra of 0.8 μm 32 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

| Vent and drain options | Available with vent and drain options to allow easy clean and thorough drainage. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-FRP Series | ||||||

|---|---|---|---|---|---|---|

| Cobber H-FRP Series Filter Housings are designed for use with HF150 Series Filter Cartridges and are mainly used for large fluid (liquid/water) flow rate applications, especially in seawater desaliation, water pre-filtration, clarification, fine chemicals, pharmaceutical, and other industrial applications. Designed for large flow rates, this filter housing requires a small area for installation. It is cost efficient and easy to operate when compared to traditional filter housings. The system will be custom designed and manufactured per customer site conditions if flow rates exceed 300 m3/h (1320 gpm). | |||||

| Modular design | Provides easy connection and dissassembly. Easily configured to match process flow and filtration requirements. | |||||

| Valve on branch tube | Allows for individual or multiple filter changeouts while system remains running | |||||

| High flow, efficient footprint, available in horizontal and vertical designs | Provides high flow in space-saving configurations | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-MBF Series | ||||||

|---|---|---|---|---|---|---|

| H-MBF Side-Inlet/Bottom Outlet Filter Housings are designed as multi-bag housings for most medium to high volume liquid filtration applications. The housings are provided with and integrated lid and sealing design. Stainless steel grid mesh directly presses on the bag filter connection, which creates a tight seal and allows for quick and efficient change-out of filter elements. | |||||

| Quality surface finishing | Mechanical polish and sand blast are available to match process requirements. | |||||

| Side Inlet, Bottom Outlet | Inlet/Outlet configurations allows easy integration into existing applications, while providing simple filter change through a swivel mounted top lid. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-EMBF Series | ||||||

|---|---|---|---|---|---|---|

| H-EMBF Side-Inlet/Side Outlet Filter Housings are designed as multi-bag housings for most medium to high volume liquid filtration applications. The housings are provided with and integrated lid and sealing design with a spring-loaded lid. Stainless steel grid mesh directly presses on the bag filter connection, which creates a tight seal and allows for quick and efficient change-out of filter elements. | |||||

| Quality surface finishing | Mechanical polish and sand blast are available to match process requirements. | |||||

| Side Inlet, Side Outlet | Inlet/Outlet configuration allows easy integration into existing applications, while providing simple filter change through a spring-loaded, auto-balanced lid design. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-LMBF Series | ||||||

|---|---|---|---|---|---|---|

| H-LMBF Bottom Inlet/Outlet Filter Housings are designed as multi-bag housings for most medium to high volume liquid filtration applications. The housings are provided with and integrated lid and sealing design. Stainless steel grid mesh directly presses on the bag filter connection, which creates a tight seal and allows for quick and efficient change-out of filter elements. | |||||

| Quality surface finishing | Mechanical polish and sand blast are available to match process requirements. | |||||

| Bottom Inlet/Outlet | Inlet/Outlet configurations allows easy integration into existing applications, while providing simple filter change through a swivel mounted top lid. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-TBF Series | ||||||

|---|---|---|---|---|---|---|

| H-TBF Top-Inlet/Bottom-Outlet Filter Housings are designed as a single bag filter housing for most low volume liquid filtration applications. WIth a top inlet design, liquid flows into the filter housing form the side inlet to the top of the filter, which helsps to establish a pressure balance and reduction or elmination of turbulence, thus protecting the filter bag. During filtraiton, liquid flows from the top to the bag filter, this keeps volume low above hte bag filter. The lid is pressed firmly against the bag filter, thus providing excellent sealing. | |||||

| Quality surface finishing | Mechanical polish, sand blast, and brushed are available to match process requirements. | |||||

| Top Inlet, Bottom Outlet | Inlet/Outlet configuration allows easy filter change through top lid. | |||||

| Economical Supports | Three-leg support bracket configuration make it easy to secure the housing to a flat surface. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-SBF Series | ||||||

|---|---|---|---|---|---|---|

| H-SBF Side-Inlet/Bottom Outlet Filter Housings are designed as a single bag fi lter housing for most low volume liquid fi ltration applications. The housings are designed with a triangle-shaped lid with one side is fi xed to the fi lter housing, which makes it convenient and easy-to-use in fi lter change operations. The housing uses a clamp ring and spring to compress the bag fi lter, ensuring a 360° seal between the housing and fi lter bag. The Z-type support allows for equal pressure against the internal basket. | |||||

| Quality surface finishing | Mechanical polish and sand blast are available to match process requirements. | |||||

Side Inlet, Bottom Outlet | Inlet/Outlet confi guration allows easy filter change through hinged top lid. | |||||

Economical Supports | Three-leg support bracket configuration make it easy to secure the housing to a flat surface. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-EBF Series | ||||||

|---|---|---|---|---|---|---|

| H-EBF Side-Inlet/Bottom Outlet Filter Housings are the most economical bag filter housings designed for most low volume liquid filtration applications in low-pressure operations. The housings are designed with a triangle-shaped lid with one side is fixed to the filter housing, which makes it convenient and easy-to-use in filter change operations. The housing uses a clamp ring and spring to compress the bag filter, ensuring a 360° seal between the housing and filter bag. The Z-type suppor t allows for equal pressure against the internal basket. | |||||

| Quality surface finishing | Mechanical polish, sand blast, and brushed are available to match process requirements. | |||||

Side Inlet, Bottom Outlet | Inlet/Outlet configuration allows easy filter change through hinged top lid. | |||||

Economical Supports | Three-leg support bracket configuration make it easy to secure the housing to a flat surface. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Gas / Liquid

| Product | Membrane | Main Construction Material | Availability Configuration | Applications | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PP | Glass Fiber | Polyester | Nylon | PES | PVDF | PTFE | PPS | Resin Fiber | PP | Nylon | Capsule | Cartridge | Liquid | Gas | |||||||||||

| GPF → | • | • | • | • | |||||||||||||||||||||

| 150PPS Filter → | • | • | • | ||||||||||||||||||||||

| PPS Filter → | • | • | • | ||||||||||||||||||||||

| High Flow Pleated → | • | • | • | • | • | • | |||||||||||||||||||

| SupaNylon Meltblown → | • | • | • | • | |||||||||||||||||||||

| EPP → | • | • | • | • | |||||||||||||||||||||

| SGD → | • | • | • | • | |||||||||||||||||||||

| NPT → | • | • | • | • | • | • | • | • | • | ||||||||||||||||

| Multipoly → | • | • | • | • | |||||||||||||||||||||

| MBFQ Phenolic → | • | • | • | ||||||||||||||||||||||

| H2D → | • | • | • | • | |||||||||||||||||||||

View Key Features & Benefits by Series | Gas / Liquid

GPF Series | ||||||

|---|---|---|---|---|---|---|

| GPF Filter Cartridges are composed of a hydrophobic PTFE membrane with polypropylene construction. They are characterized by a high filtration area, and are highly recommended for air and gas filtration for tanks and gases in the ink or industrial industries. | |||||

| Hydrophobic PTFE membrane | Inherently hydrophobic to prevent liquid from passing Exceptionally high flow rates with low pressure drops Recommended for all air and gas filtration in the ink and industrial industries | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

150PPS Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter™ 150PPS Core-less Filter Cartridges are designed without a core for environmentally-friendly applications where high performance and low cost are paramount. These filters feature 100% Polyphenylene Sulphide (PPS) media guaranteeing excellent chemical stability, electric isolation, and thermostability. Large diameter core-less cartridges feature low differential pressure, particularly suitable for high flow filtration. | |||||

| Core-Less, Polyphenylene Sulphide (PPS) Media | Low differential pressure media with a large diameter cartridge making it suitable for high liquid flow Ideal for high flow and high temperature applications. PPS media provides excellent performance in chemical stability, electric isolation, and thermo-stability. Ideally designed to fit with 316L stainless steel core. Quick and easy installation/removal over the core which leaves the core in the filter housing. (Separate stainless steel core remains in the filter which results in a lower disposal cost and more environmentally-friendly.) | |||||

| Standard Size/ Construction | Direct replacement for other core-less products. Simple structure with easy operation and low installation and operational costs. | |||||

| Quality Assurance | Manufactured in a facility which adheres to ISO 9001 Practices. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

PPS Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter™ PPS Filter Cartridges are designed where high performance and high temperature are paramount. These filters feature Polyphenylene Sulphide (PPS) media for excellent chemical thermostability. | |||||

| Polyphenylene Sulphide (PPS) Media | Ideal for high temperature applications. PPS media provides excellent performance in chemical stability, electric isolation, and thermo-stability. Ideally designed to fit with DOE stainless steel housings. | |||||

| Quality Assurance | Manufactured in a facility which adheres to ISO 9001 Practices. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

High Flow Filter System | ||||||

|---|---|---|---|---|---|---|

| Cobetter Hgh Flow Filters are large diameter, single open-ended pleated cartridge filters for high flow applications. The filter has an open-pleated construction with a 152 mm (6") diameter, high filtration area, and high flow rates up to 90m3/hr (396 gpm). These filters can be can be used in a wide variety of applications with large flow rate requirements and short downtime for change-out. | |||||

Graded pore size pleated depth filter construction | Large filtration area and depth filter construction provides high flow rates combined with low pressure drops and long service life. Eliminates particles according to pore size distribution which significantly increases filter lifetime. Flow rate configuration from inside-out ensures that all contamination is held within the single-open end of the filter. Quick and easy change-out. Reduces number of filters by 90%. | |||||

Ergonomical Handle | Facilitates fast and easy installation and removal without special tools. | |||||

Quality Assurance | These products are manufactured in a facility which adheres to ISO 9001:2015 Practices. | |||||

Indirect Food Additive | All component materials meet the FDA Indirect Food Additive requirements cited in 21 CFR 177–182. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

SupaNylon Melt Blown | ||||||

|---|---|---|---|---|---|---|

| SupaNylon® Melt Blown Filters are made of 100% nylon melt-blown depth media without surfactants, binders, or adhesives. Melt-blown depth media consists of gradient pores. The cartridge is capable of efficiently capturing particles of different sizes with a great flow rate and lifetime. These cartridges have been designed for applications where polypropylene filters cannot be used. | |||||

| Melt-blown 100% nylon media with gradient pores | Provides high contaminant hold capacity and high removal efficiency at low pressure drop Long service life, high flow rate due to the different linear diameters and unique interwoven density control process. SupaNylon has a porosity far beyond that of similar products, which results in lower pressure loss across the cartridge and higher contaminant-holding capacity. Stable pore structure and high-purity filtration. Manufactured with no wetting agents, solvents, surfactants, binders, or adhesives. Wide range of filtration rates from 0.5 μm to 40 μm to meet various operation conditions. | |||||

| Quality Assurance | Manufactured in a facility which adheres to ISO 9001 Practices. | |||||

| Particle shedding | Autoclaved filter effluent meets the requirements in USP <788> for large volume parenterals. | |||||

| Cleanliness | Food Contact Declaration 2008/39/EC (2002/72/EC) | |||||

| Non-fiber release | Component materials meet the criteria for a “Non-fiberreleasing filter” as defined in 21 CFR210.3 (b) (6). | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

EPP Series | ||||||

|---|---|---|---|---|---|---|

| EPP Filter Cartridges are composed entirely of nominally rated pleated polypropylene microfiber which provides great filtration performance with a low cost. Characteristics include high flow rates, high contaminant holding capacity and filtration efficiency making it the ideal solution for the pre-filtration of liquids. | |||||

| All Polypropylene construction | Broad chemical compatibility makes it suitable for acids, bases, and solvents High filtration efficiency Pleated surface area provides superior flow rate and extended service life 100% thermally-welded design eliminates the need for adhesives which can be a contamination source Available in nominal ratings from 0.1μm to 25μm for precise particle removal | |||||

| Quality Assurance | Manufactured in a facility which adheres to ISO 9001 Practices. 100% Integrity tested and lot traceable | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

SGD Series | ||||||

|---|---|---|---|---|---|---|

| (SGD) Guard Filter Cartridges are composed of super-fine glass fiber media with a suppor t layer of polypropylene. Glass fiber media has an inherently absorptive characteristic that enhances filter retention capability and are 1/3rd the diameter of normal fibers. SGD filter car tridges offer excellent efficiency, high flow rates and high contaminant-holding capability. The single cage construction provides high surface area, stable length control, and no leakage risk. SGD filter cartridges can protect expensive RO membranes. These filters are ideal for a wide range of industrial and water treatment applications. | |||||

| Super-fine glass micro-fiber membrane | High porosity for high flow rates and low pressure drops Nominal particle retention efficiency at rated pore size Stiff structure of glass micro-fiber media provides high flow rate Glass fiber media has high contaminant holding capacity and inherently adsorptive effect which features its gel removal ability Extremely good chemical compatibility | |||||

| Quality Assurance | Manufactured in a facility which adheres to ISO 9001 Practices. 100% Integrity tested and lot traceable | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

NPT Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter® NPT Series Capsule Filters are available in varying sizes and filter media including depth filters, liquid grade filters and gas filters. They were developed to meet a wide range of chemical, industiral, and ink filtration requirements. The NPT Capsule Filter Series contains a wide-range of filtration media options (PTFE, PES, PVDF, and PP), in a variety of filter sizes and effective filtration areas. | |||||

| Non-fiber release design | Thermally-bonded fiber polypropylene forms a stable structure and ensures no fibers are released | |||||

| Thermal welding technology | No adhesive resins to ensure capsule filter's cleanliness and longuse pressure endurance | |||||

| Available in a variety of filtration media (PTFE/PES/ PVDF/PP) = | Filters available with media options to match the specific flow, retention, and performance requirements of low-flow chemicals, industrial, and ink filtration applications | |||||

| No surfactants or binders | Clean, low-extractable filters | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

MultiPoly Series | ||||||

|---|---|---|---|---|---|---|

| MultiPoly® Filter Cartridges are composed of multi-layered pleated polypropylene. These filters have a depth filter design that includes graded pore size and high contaminant holding capacity which eliminates contaminants (including gels and agglomerates) in highly viscous liquids, and avoids filter surface plugging. The graded pore size distribution from coarse (upstream) to fine (downstream) removes particles gradually and extends the filter’s service life making it especially suited for suspended particulates, colloids, and viscous liquids. The NPT Capsule Filter Series contains a wide-range of filtration media options (PTFE, PES, PVDF, and PP), in a variety of filter sizes and effective filtration areas. | |||||

| 5 to 7 layers of PP media with graded pore size distribution | Enables additional particle loading and high contaminant holding capacity Low pressure drop, long service life, filtration efficiency | |||||

| Multi-layer nano fiber media | Provides excellent removal of contaminants including gels and agglomerates | |||||

| Polypropylene construction | Excellent chemical compatibility | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

MBFQ Phenolic Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter™ MBFQ Phenolic Resin Filter Cartridges are constructed of micro fiber phenolic resin through a special process to deliver high solvent resistance, high temperature resistance, high flow rate, low pressure differential an long service life. The filters are ideal for use with high viscosity liquids, and solvent-based materials, at high temperatures. | |||||

| Pheno-formaldehyde resin fiber media | Low differential pressure media with a large diameter cartridge making it suitable for high liquid flow Ideal for high flow and high temperature applications. Excellent performance with solvent-based liquids, highviscosity liquids, and liquids at high temperatures Media shows no deformation under high temperature and high pressure operating conditions | |||||

| Interweave, graduated pore-size construction | The unique interweave density control process delivers an extremely high-porosity media, with large pore size on the upstream and a smaller pore size on the downstream, enabling lower pressure drop while delivering higher contaminant-holding capacity | |||||

| Groove construction | Unique construction process including grooving on its surface increases filtration area impurity removal capacity | |||||

| Quality Assurance | Manufactured in a facility which adheres to ISO 9001 Practices | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H2D Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter™ H2D Filter Cartridges are constructed of graded pore size, high-density pleated polypropylene media. The filters deliver high flow rates, high contaminant-holding capacity for long service life filtration. | |||||

| All polypropylene construction | Ideal for filtration of a wide variety of water and low-viscosity chemical filtration. Provides cleanliness and strength with good chemical compatibility | |||||

| Graded-density, pleated filter media | Large pore size on the upstream and a smaller pore size on the downstream enables lower pressure drop while delivering high contaminant-holding capacity, and long service life Available in removal ratings from 0.6 to 70 μm for use with a wide range of water and chemical filtration at high flow rates ≥ 99% efficiency | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

FILTERS BY INDUSTRY

NEED HELP?

We have a team of filtration experts that can help with all of your filtration needs. If you’re not sure what you’re looking for, fill out this request form or contact us here and one of our team members will be in touch with product recommendations.

ORDER ONLINE

We have a selection of filtration products on our e-commerce website, but there are many more options available. If you’re looking for something specific, tell us about it here.