High Purity

FFA or PTFE lined filter stainless steel housing are needed for high purity applications or aggressive chemistries that would degrade raw stainless steel or other plastics. The use of these housings are critical in industries like microelectronics where the purity of the chemistry is critical in making the intricate circuitry that is only nanometer on the semiconductor chips.

| Product | Housing Material | Configuration | Internal Filter | Applications | ||||

|---|---|---|---|---|---|---|---|---|

| PFA or PTFE | SS | Single Round | Multi Round | 222 | Liquid | |||

| Fluorolink PFA → | • | • | • | • | ||||

| H-CPF PTFE Coated Filter → | • | • | • | • | • | • | ||

View Key Features & Benefits by Series | High Purity

Fluorolink Series | ||||||

|---|---|---|---|---|---|---|

| Fluorolink™ is an all-fluoropolymer housing designed for ultra-high purity chemicals, chemical blends, and certain agressive chemicals applications. | |||||

Industry standard fittings | Industry standard flared fittings for easy installation | |||||

Compact design | Compact design is space saving and ideal for chemical distribution and on-tool applications | |||||

High temperature rating | Temperature rating to 100°C is ideal for the majority of chemical dispense, clean, and etch processes | |||||

Three locking ring choices | Three locking ring material choices can be matched to chemicals and solvents for robust operation and long life | |||||

Sturdy mounting bracket | Integrated mounting bracket enables secure installation | |||||

Large vents/drains | Larger 1/2” vents and drains promote faster venting and draining to reduce startup and filter changeout times | |||||

Chemical-compatible O-rings | TEV O-ring and Chemraz® options from Banner Industries offer complete range of chemical compatibility and a leak tight seal | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-CPF PTFE Series | ||||||

|---|---|---|---|---|---|---|

| H-CPF PTFE-Lined Filter Housings are designed for use with corrosive fluids (acids & bases) in fine chemical applications. Fluid contact area is composed of PTFE or PFA which solves chemical compatibility issues with stainless steel filter housings, especially for use with aggressive acids. The housings are customizable for flow rate requirements. | |||||

| Fluoropolymer Lined Flow Path | Allows chemical compatibility with acids and bases - corrosive fluids, including Nitric Acid (conc.), Sulfuric Acid (conc.), Sodium Hydroxide (conc.), THF, TFA, and other chemicals | |||||

| Multiple Configurations to Match Flow Requirements | Available in 1, 3, 5, and 7 round configurations, and custom sizes are available. Bowl designs available for 5, 10, 20, 30, and 40- inch filter lengths. | |||||

| High Operating Temperature | With a max. operating temperature of 150°C (302°F), the housings are ideal for use in a wide range of elevated chemical flows. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Lab Testing

Membrane filter holders are utilized for small scale testing in laboratory evaluation of the filtration media or filtered product. The membrane can be utilized to simulate small scale testing for larger processes or test products for particulate evaluations.

| Product | Housing Material | Internal Filter | Applications |

|---|---|---|---|

| SS | Membrane Disc | Liquid | |

| H-DMF Membrane Holder → | • | • | • |

| H-TMF Membrane Holder → | • | • | • |

| H-DMF-T Membrane Holder → | • | • | • |

| 47mm PPF Holders → | • | ||

| Vacuum Manifold → | • | ||

| Glass Holder → | • |

View Key Features & Benefits by Series | Gas or Vent

H-DMF Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter H-DMF Stainless Steel Membrane Holders are designed for liquid/ gas classification or sterilization by pressure filtration. Tri-Clamp sanitary inlet/outlet connections have no screw heads to trap contaminants and are easy to clean. Housings are available in 47 mm, 90 mm, 142 mm, and 293 mm diameter configurations. Each component can be completely disassembled and cleaned. Sanitary grade finished polishing of Ra < 0.38μm (15 μin.) make these housings suitable for a variety of sanitary industrial and chemical applications. | |||||

| Easy individual component disassembly | Each component can be completely disassembled and cleaned | |||||

| Tri-Clamp or screw connections | Design allows for safe, easy sealing of connections | |||||

| Quality surface finishing | With an internal bowl Ra of 0.38μm (15 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-TMF Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter H-TMF Stainless Steel Membrane Holders are designed to meet GMP standards and cleanliness. Each component can be completely disassembled and cleaned. Sanitary grade finished polishing of Ra < 0.38μm (15 μin.) make these housings suitable for a variety of sanitary industrial and chemical applications. The body and internal membrane supports are composed of stainless steel and the mechanical sealing eliminates the need of a gasket. These membrane holders are suitable for vacuum filtration in combination with a vacuum bottle. The simple construction and ease of operation allows analysis for a large variety of fluids. | |||||

| Easy individual component disassembly | Each component can be completely disassembled and cleaned | |||||

| Quality surface finishing | With an internal bowl Ra of 0.38μm (15 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-DMF-T Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter H-DMF Stainless Steel Membrane Holders are designed for use in liquid filtration when a high level of cleanliness is required , including lab analysis and product research/development. Each component can be completely disassembled and cleaned. Sanitary grade finished polishing of Ra < 0.38μm (15 μin.) make these housings suitable for a variety of sanitary industrial and chemical applications. | |||||

| Easy individual component disassembly | Each component can be completely disassembled and cleaned | |||||

| FNPT Connections | Design allows for safe, easy sealing of connections | |||||

| Quality surface finishing | With an internal bowl Ra of 0.38μm (15 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

47 mm PP Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter 47 mm plastic membrane filter holders are designed for filtration of small volumes of liquids, laboratory testing, and filter evaluations. The holders are constructed with a male 1/4 inch NPT inlet and outlet that ha s a molded/integrated female Luer connection at center. The 47mm filter holders are reusable and accept 47 and 50mm diameter membranes. | |||||

| All polyproplene construction with silicone o-ring seal | Ensures cleanliness, ease of assembly, and leak-free seal | |||||

| Designed for 47 mm and 50 mm membranes discs | Can be easily used with standard-sized membrane discs | |||||

| Male 1/4" NPT I/O, with Female Luer Slip at center | Easy connections to standard fittings. Syringe Male Luer slip compatible | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Vacuum Manifold Series | ||||||

|---|---|---|---|---|---|---|

| Vacuum filtration is used primarily in microbiological and analytical procedures that involve collecting a particulate (bacteria, precipitate, etc.) from a liquid suspension. Liquid poured into a funnel passes through a filter, which retains the particulate, and filtrate can be collected into a filter flask, directly or via a vacuum manifold. Cobetter lab stainless steel vacuum filtration manifolds are available in 3-branch or 6-branch unit configurations. The multi-branch vacuum filtration manifold is designed to filter several samples at the same time using a vacuum filtration pump attached directly to the manifold. | |||||

Each vacuum filtration station has an individual control valve for maximum flexibility | ||||||

Stainless steel manifold construction (SS 316L) ensures a high level of chemical resistance and is easy to clean | ||||||

3 or 6 unit configuration | ||||||

Glass and stainless steel funnels available | ||||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Glass Filter Holder Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter’s Glass Vacuum Filter unit is used primarily in microbiological and analytical procedures that involve particle retention (bacteria, precipitate, etc.) from a liquid suspension. Liquid poured into the funnel passes through a filter, which retains the particulate, and filtrate can be collected into a conical flask, when connected to a vacuum source. This product is made of high-quality extra hard glass. It is crystal-clear giving excellent product visibility. Its robust construction allows for extended product life in a busy laboratory environment. The filter unit can also be used for filtration of mobile phase for HPLC and other analytical procedures. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Gas or Vent Filtration

Gas filtration provides efficient reliable particle removal of high purity gas and air to critical process tools. Cobetter makes stainless steel filter housing for venting and pressurized systems that are essential for current manufacturing technologies. They are designed to meet todays gas processes for high and low flow applications.

| Product | Housing Material | Configuration | Internal Filter | Applications | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SS | Single Round | 222 | 226 | DOE | Liquid | Gas | ||||

| H-VCF Vent → | • | • | • | • | • | |||||

| H-VCF II &III Vent → | • | • | • | • | • | |||||

| H-HCF Gas Filter → | • | • | • | • | • | • | ||||

| H-HCF II Gas Filter → | • | • | • | • | • | • | ||||

| H-CCF Single Round → | • | • | • | • | • | • | • | |||

| H-CCF Machined Head → | • | • | • | • | • | • | • | |||

View Key Features & Benefits by Series | Gas or Vent Filtration

H-VCF Series | ||||||

|---|---|---|---|---|---|---|

| H-VCF Filter Housings are designed for use in food & beverage, pharmaceutical, and other applications to sterilize the air before it flows into a tank, while maintaining pressure balance inside and outside the housing. Sanitary grade finished polishing of Ra < 0.38μm (15 μin.) make these housings suitable for a variety of sanitary industrial and chemical applications. | |||||

| Internal flow design | Prevents particles from flowing into housing, thus protecting filter housing from damage and maintaining clean flow rates through filter | |||||

| Tri-clamp connection | Design allows for safe, easy sealing of bowl to housing head | |||||

| Quality surface finishing | With an internal bowl Ra of 0.38μm (15 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-VCFII Series | ||||||

|---|---|---|---|---|---|---|

| H-VCF Filter Housings are available in heated (H-VCF III) and unheated (H-VCF II) configurations with sanitary grade finished polishing of Ra < 0.38μm (15 μin.) making them suitable for a variety of sanitary, industrial and chemical applications. The housings are available in three standard-size tri-clamp I/O connections for easy integration into existing tools/processes. The H-VCF III version includes an electric heater jacket with cover and easy-to-set automatic temperature control. | |||||

| Sealed heated housing jacket with advanced electronic temperature control system | Keeps filters dry by heat which helps guarantee flow rates High temperature environment prevents germ growth | |||||

| Internal flow design | Prevents particles from flowing into housing, thus protecting filter housing from damage and maintaining clean flow rates through filter | |||||

| Tri-clamp connection | Design allows for safe, easy sealing of bowl to housing head | |||||

| Quality surface finishing | With an internal bowl Ra of 0.38μm (15 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-GCF Series | ||||||

|---|---|---|---|---|---|---|

| H-GCF Gas Filter Housings are designed for air/gas filtration in biotechnology, chemical, electronic, and food & beverage industries. The housings are compatible with standard cartridges to meet the requirements of air/gas filtration. Endcap design of the housing is Code 7 (external 226 double o-ring with 2 locking tabs) which provides safe and secure sealing. Features include mechanical polishing with a Ra of 15 μin (0.3 μm), easy-to-clean, and thorough drainage which eliminates concerns about remaining liquids. Electro-polishing finish is also an available option. | |||||

| Designed for Code 7 cartridges | Provides safe and secure sealing of cartridges with 226 double o-ring and 2 locking tabs | |||||

| Quality surface finishing | With an internal Ra of 0.38 μm (15 μin.) and external Ra of 0.4 μm (16 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. All electropolishing is also available | |||||

Vent and drain options

| Available with vent and drain options to allow easy clean and thorough drainage | |||||

Standard housing options

| Housing flange connections are designed in accordance with international standards to allow connection to industry-standard connections | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-GCF II Series | ||||||

|---|---|---|---|---|---|---|

| H-GCF Gas Filter Housings are designed for medium and high-pressure air/gas filtration in biotechnology, chemical, electronic, and food & beverage industries. The housings are compatible with standard cartridges to meet the requirements of air/gas filtration. Endcap design of the housing is external 226 double o-ring with 2 locking tabs which provides safe and secure sealing. Features include mechanical polishing with a Ra of 15 μin (0.3 μm), e asy-to-clean, and thorough drainage which eliminates concerns about remaining liquids. Electro-polishing finish is also an available option. | |||||

| Designed for 226 cartridges | Provides safe and secure sealing of cartridges with 226 double o-ring and 2 locking tabs | |||||

| Quality surface finishing | With an internal Ra of 0.38 μm (15 μin.) and external Ra of 0.4 μm (16 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. All electropolishing is also available | |||||

Vent and drain options

| Available with vent and drain options to allow easy clean and thorough drainage | |||||

Standard housing options

| Housing flange connections are designed in accordance with international standards to allow connection to industry-standard connections | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-CCF Series | ||||||

|---|---|---|---|---|---|---|

| H-CCF Filter Housings feature T-line configuration which allows for easy installation into various tools and locations. The bowl is sanitary grade and has a finished polishing of Ra < 0.38μm (15 μin.) making it suitable for a variety of applications. Since the housing is a compact structure, the top of the filter housing can be supported to rigid pipe. The tri-clamp connection of the housing makes it easy to remove the bowl and replace filter elements. There is no liquid spillover during the replacement process, since the bowl can drop down after release of the tri-clamp. In addition, the drain valve located at the bottom of the filter housing allows for easy drainage. | |||||

| T-line configuration with top inlet and top outlet | T-line configuration allows tubing to be kept inline | |||||

| Tri-clamp bowl connection | No liquid spillover when replacing filter cartridges as bowl can drop down after release of clamp Design allows for safe, easy sealing of bowl to housing head | |||||

| Drain on housing bottom | Easy to drain | |||||

| Quality surface finishing | With an internal bowl Ra of 0.38μm (15 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-CCF Machined Head Series | ||||||

|---|---|---|---|---|---|---|

| H-CCF Filter Housings feature T-line configuration which allows for easy installation into various tools and locations. The bowl is sanitary grade and has a finished polishing of Ra < 0.38μm (15 μin.) making it suitable for a variety of applications. Since the housing is a compact structure, the top of the filter housing can be supported to rigid pipe. The tri-clamp connection of the housing makes it easy to remove the bowl and replace filter elements. There is no liquid spillover during the replacement process, since the bowl can drop down after release of the tri-clamp. In addition, the drain valve located at the bottom of the filter housing allows for easy drainage. | |||||

| T-line configuration with top inlet and top outlet | T-line configuration allows tubing to be kept inline | |||||

| Tri-clamp bowl connection | No liquid spillover when replacing filter cartridges as bowl can drop down after release of clamp Design allows for safe, easy sealing of bowl to housing head | |||||

| Drain on housing bottom | Easy to drain | |||||

| Quality surface finishing | With an internal bowl Ra of 0.8 μm (32 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Bag Filtration

Bag filters housing are designed for bulk removal of particles in a fluid path. They allow for high flow rates and quick clarification of the liquid with easy change out of the filtration bags.

| Product | Housing Material | Configuration | Internal Filter | Applications | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SS | Single Round | Multi Round | 222 | 226 | DOE | 116 | 334 | HF150 | Lenticular | Bag | Liquid | |||||||||

| H-MBF Bag Multiround (Side In/ Bottom Out) → | • | • | • | • | ||||||||||||||||

| H-EMBF Bag Multiround (Side In/ Side Out) → | • | • | • | • | ||||||||||||||||

| H-LMBF Bag Multiround (Bottom I/O) → | • | • | • | • | ||||||||||||||||

| H-TBF Single Round Bag (Top In, Bottom Out) → | • | • | • | • | ||||||||||||||||

| H-SBF Single Round Bag (Side In, Bottom Out) → | • | • | • | • | ||||||||||||||||

| H-EBF Single Round Bag (Side In, Bottom Out) → | • | • | • | • | ||||||||||||||||

| S-SIF Filter Systems → | • | • | • | • | • | • | • | • | • | • | • | • | ||||||||

View Key Features & Benefits by Series | Bag Filtration

H-MBF Series | ||||||

|---|---|---|---|---|---|---|

| H-MBF Side-Inlet/Bottom Outlet Filter Housings are designed as multi-bag housings for most medium to high volume liquid filtration applications. The housings are provided with and integrated lid and sealing design. Stainless steel grid mesh directly presses on the bag filter connection, which creates a tight seal and allows for quick and efficient change-out of filter elements. | |||||

| Quality surface finishing | Mechanical polish and sand blast are available to match process requirements. | |||||

| Side Inlet, Bottom Outlet | Inlet/Outlet configurations allows easy integration into existing applications, while providing simple filter change through a swivel mounted top lid. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-EMBF Series | ||||||

|---|---|---|---|---|---|---|

| H-EMBF Side-Inlet/Side Outlet Filter Housings are designed as multi-bag housings for most medium to high volume liquid filtration applications. The housings are provided with and integrated lid and sealing design with a spring-loaded lid. Stainless steel grid mesh directly presses on the bag filter connection, which creates a tight seal and allows for quick and efficient change-out of filter elements. | |||||

| Quality surface finishing | Mechanical polish and sand blast are available to match process requirements. | |||||

| Side Inlet, Side Outlet | Inlet/Outlet configuration allows easy integration into existing applications, while providing simple filter change through a spring-loaded, auto-balanced lid design. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-LMBF Series | ||||||

|---|---|---|---|---|---|---|

| H-LMBF Bottom Inlet/Outlet Filter Housings are designed as multi-bag housings for most medium to high volume liquid filtration applications. The housings are provided with and integrated lid and sealing design. Stainless steel grid mesh directly presses on the bag filter connection, which creates a tight seal and allows for quick and efficient change-out of filter elements. | |||||

| Quality surface finishing | Mechanical polish and sand blast are available to match process requirements. | |||||

| Bottom Inlet/Outlet | Inlet/Outlet configurations allows easy integration into existing applications, while providing simple filter change through a swivel mounted top lid. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-TBF Series | ||||||

|---|---|---|---|---|---|---|

| H-TBF Top-Inlet/Bottom-Outlet Filter Housings are designed as a single bag filter housing for most low volume liquid filtration applications. WIth a top inlet design, liquid flows into the filter housing form the side inlet to the top of the filter, which helsps to establish a pressure balance and reduction or elmination of turbulence, thus protecting the filter bag. During filtraiton, liquid flows from the top to the bag filter, this keeps volume low above hte bag filter. The lid is pressed firmly against the bag filter, thus providing excellent sealing. | |||||

| Quality surface finishing | Mechanical polish, sand blast, and brushed are available to match process requirements. | |||||

| Top Inlet, Bottom Outlet | Inlet/Outlet configuration allows easy filter change through top lid. | |||||

| Economical Supports | Three-leg support bracket configuration make it easy to secure the housing to a flat surface. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-SBF Series | ||||||

|---|---|---|---|---|---|---|

| H-SBF Side-Inlet/Bottom Outlet Filter Housings are designed as a single bag fi lter housing for most low volume liquid fi ltration applications. The housings are designed with a triangle-shaped lid with one side is fi xed to the fi lter housing, which makes it convenient and easy-to-use in fi lter change operations. The housing uses a clamp ring and spring to compress the bag fi lter, ensuring a 360° seal between the housing and fi lter bag. The Z-type support allows for equal pressure against the internal basket. | |||||

| Quality surface finishing | Mechanical polish and sand blast are available to match process requirements. | |||||

Side Inlet, Bottom Outlet | Inlet/Outlet confi guration allows easy filter change through hinged top lid. | |||||

Economical Supports | Three-leg support bracket configuration make it easy to secure the housing to a flat surface. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-EBF Series | ||||||

|---|---|---|---|---|---|---|

| H-EBF Side-Inlet/Bottom Outlet Filter Housings are the most economical bag filter housings designed for most low volume liquid filtration applications in low-pressure operations. The housings are designed with a triangle-shaped lid with one side is fixed to the filter housing, which makes it convenient and easy-to-use in filter change operations. The housing uses a clamp ring and spring to compress the bag filter, ensuring a 360° seal between the housing and filter bag. The Z-type suppor t allows for equal pressure against the internal basket. | |||||

| Quality surface finishing | Mechanical polish, sand blast, and brushed are available to match process requirements. | |||||

Side Inlet, Bottom Outlet | Inlet/Outlet configuration allows easy filter change through hinged top lid. | |||||

Economical Supports | Three-leg support bracket configuration make it easy to secure the housing to a flat surface. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

S-SIF Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter S-SIF Filtration System Series are specifically designed and engineered for industrial fluid filtration. They contain all the necessary componentsincluding pressure source (pump), filter housings, stainlesssteel pipes, pressure gauge, drain valve, and filtration trolley. The system comesfully assembled, and requiresonly inlet and outlet connections. The system isa multi-stage filtration system and the filter housingscan meet specific requirementsand needs. Cobetter can also provide the filter cartridgesinside the system to meet application requirements. In addition, Cobetter can supply different pressure sources: stainlesssteel water pump, gear pumps, pneumatic pumps, or air diaphragm pumps. Single-round filter housing systemsuse Tri-clamp connections, while other systemsuse flange connections. Design pressure can reach 10 bar (145 psi). | |||||

| Quality surface finishing | Mechanical polished surfaces with sanitary grade and industrial grade polishing available. | |||||

| Multiple Configurations to Match Process Flows | S-SIF I: 3 Stages - meet the needs of fluids that contain a low solid content but require a high filter retention. S-SIF II: 1st Stage Bag Housing Series; 2nd- 3rd Stages. Liquid Filter Housing – meet the needs of fluids with a high solid content. Use of filter bags in the first stage is a more economical method of removing large pore size particles and yields higher filter retention in the latter two stages. S-SIF III: Customized Filtration System | |||||

Economical Supports | Three-leg support bracket configuration make it easy to secure the housing to a flat surface. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Lenticular

Lenticular filtration has a high capacity and filtration performance that make them a cost effective solution for a variety of industries like Food & Beverage. The lenticular housing allow for easy installation of 12 or 16 in diameter filter elements for a quick turn around time.

| Product | Housing Material | Internal Filter | Applications |

|---|---|---|---|

| SS | Lenticular | Liquid | |

| H-CSD Lenticular → | • | • | • |

View Key Features & Benefits by Series | Lenticular

H-CSD Lenticular Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter H-CSD Lenticular Series Filter Housings are designed for use with H-CSD lenticular series filter modules. The housings are designed for sanitary requirements with well-polished surfaces to ensue no residual liquids and easy throughput for cleaning. The housings are available in 304 or 316L stainless steel, which ensures strong corrosion resistance for a wide range of applications. The bottom in/bottom out flow pattern eliminates turbulent flow, then enhancing filtration efficiency. Maximum stack height of four stacks meets high flow-rates requirements. | |||||

High flow, efficient footprint for H-CSD Lenticular modules

| Provides high purity filtration and high flow in space-saving configurations | |||||

| Quality surface finishing | With an internal Ra of 0.38 μm (15 μin.) and external Ra of 0.4 μm 16 μin), the sanitary surface finish prevents entrapment or build-up of contaminants | |||||

| Vent and drain options | Available with vent and drain options to allow easy clean and thorough drainage | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Stainless Steel Cartridge Housing

Cobetter offers single and multi round stainless steel cartridge filter housings that can be utilized at a variety of flow rates and applications. The housings have are available in 304 and 316L stainless steel construction in sizes from mini to 40″ long cartridges. They can be configured to meet your flow and fitting requirements.

| Product | Housing Material | Configuration | Internal Filter | Applications | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PFA or PTFE | SS | Single Round | Multi Round | 222 | 226 | DOE | 116 | 334 | HF150 | Lenticular | Bag | Liquid | Gas | |||||||||||

| H-SCF Sanitary → | • | • | • | • | • | • | ||||||||||||||||||

| H-VCF Vent → | • | • | • | • | • | |||||||||||||||||||

| H-VCF II &III Vent → | • | • | • | • | • | |||||||||||||||||||

| Multi Round Sanitary (Bottom I/O) → | • | • | • | • | • | • | ||||||||||||||||||

| Multi Round Sanitary (Side In/Bottom Out) → | • | • | • | • | • | • | ||||||||||||||||||

| H-SPF In-Line Sanitary → | • | • | • | • | • | • | ||||||||||||||||||

| H-HCF Gas Filter → | • | • | • | • | • | • | ||||||||||||||||||

| H-HCF II Gas Filter → | • | • | • | • | • | • | ||||||||||||||||||

| H-SCFII Mini Filter → | • | • | • | • | ||||||||||||||||||||

| H-CPF PTFE Lined Filter → | • | • | • | • | • | • | ||||||||||||||||||

| H-CCF Single Round Industrial → | • | • | • | • | • | • | • | |||||||||||||||||

| H-CCF Machined Head Industrial → | • | • | • | • | • | • | • | |||||||||||||||||

| H-SICF Industrial Multi-round → | • | • | • | • | • | • | ||||||||||||||||||

| S-SIF Filter Systems → | • | • | • | • | • | • | • | • | • | • | • | • | ||||||||||||

View Key Features & Benefits by Series | Stainless Steel Cartridge Housing

H-SCF Series | ||||||

|---|---|---|---|---|---|---|

| H-SCF Sanitary Filter Housings are specifically designed as a single-round filter housing for low volume liquid filtration. The H-SCF is strongly recommended for use in life science filtration applications, as it meets sanitary requirements and GMP standards. Features include mechanical polishing with a Ra of 15 μin (0.3 μm), easy-to-clean, and thorough drainage, which eliminates concerns about remaining liquids. Electro-polishing finish is also an available option. | |||||

| Quality surface finishing | With an internal Ra of 0.38 μm (15 μin.) and external Ra of 0.4 μm (16 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. All electropolishing is also available | |||||

| Enlarged vent and drain with stepped thread connections | Internal diameter connects with 8mm tube. Integrated vent and drain with stepped thread ensure secure tube connetion during drain and vent operations. | |||||

| Quick-release sectional closure clamp | Quick disassembly of housing bowl Provides increase pressure endurance by 20% compared to normal clamps Provides perfect sealing for PTFE o-rings with max. operating pressure up to 10 bar (145 psi) | |||||

| Adjustable nut on legs | Allows for filter length to be adjusted | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-VCF Series | ||||||

|---|---|---|---|---|---|---|

| H-VCF Filter Housings are designed for use in food & beverage, pharmaceutical, and other applications to sterilize the air before it flows into a tank, while maintaining pressure balance inside and outside the housing. Sanitary grade finished polishing of Ra < 0.38μm (15 μin.) make these housings suitable for a variety of sanitary industrial and chemical applications. | |||||

| Internal flow design | Prevents particles from flowing into housing, thus protecting filter housing from damage and maintaining clean flow rates through filter | |||||

| Tri-clamp connection | Design allows for safe, easy sealing of bowl to housing head | |||||

| Quality surface finishing | With an internal bowl Ra of 0.38μm (15 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-VCFII Series | ||||||

|---|---|---|---|---|---|---|

| H-VCF Filter Housings are available in heated (H-VCF III) and unheated (H-VCF II) configurations with sanitary grade finished polishing of Ra < 0.38μm (15 μin.) making them suitable for a variety of sanitary, industrial and chemical applications. The housings are available in three standard-size tri-clamp I/O connections for easy integration into existing tools/processes. The H-VCF III version includes an electric heater jacket with cover and easy-to-set automatic temperature control. | |||||

| Sealed heated housing jacket with advanced electronic temperature control system | Keeps filters dry by heat which helps guarantee flow rates High temperature environment prevents germ growth | |||||

| Internal flow design | Prevents particles from flowing into housing, thus protecting filter housing from damage and maintaining clean flow rates through filter | |||||

| Tri-clamp connection | Design allows for safe, easy sealing of bowl to housing head | |||||

| Quality surface finishing | With an internal bowl Ra of 0.38μm (15 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Multi-Round (Bottom I/O) Series | ||||||

|---|---|---|---|---|---|---|

| H-S*F Series Multi-Round Sanitary Filter Housings are specifically designed for liquid filtration at varying flow rates, including high flow rates. The H-S*F Multi-Round housings are strongly recommended for use in life science and high purity filtration applications, as it meets s anitary requirements and GMP standards. Features include mechanical polishing with a Ra of 15 μin (0.3 μm), easy-to-clean, and thorough drainage, which eliminates concerns about remaining liquids. Electro-polishing finish is also an available option for housings with 12 rounds or less. | |||||

| Quality surface finishing | With an internal Ra of 0.38 μm (15 μin.) and external Ra of 0.4 μm 16 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. All electropolishing is also available | |||||

Enlarged vent and drain with stepped thread connections

| Internal diameter connects with 8mm tube. Integrated vent and drain with stepped thread ensure secure tube connection during drain and vent operations. | |||||

| Quick-release sectional closure clamp or toggle bolts | Quick disassembly of housing bowl | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Multi-Round (Side In, Bottom Out) Series | ||||||

|---|---|---|---|---|---|---|

| The Multi-Round Sanitary Filter Housings are designed for use in food & beverage, pharmaceutical, and other applications designed for filtration requiring 15 or more filter elements. The flow pattern is side-in and bottom out. The housing is available in three configurations including the easy-changeout version which has the filter changeout cover located on a pivot support at the top of the housing. Sanitary grade finished polishing of Ra < 0.38μm (15 μin.) make these housings suitable for a variety of sanitary industrial and chemical applications. | |||||

| Side-in and bottom-out flow pattern with multiple filter changeout configurations | Efficient flow pattern available in top opening and bottom opening configurations to allow efficient filter changeout as well as rigorous cleaning capabilities. | |||||

Tri-clamp connection

| Design allows for safe, easy sealing of connections | |||||

| Quality surface finishing | With an internal bowl Ra of 0.38μm (15 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-SPF Series | ||||||

|---|---|---|---|---|---|---|

| H-SPF In-Line Sanitary Filter Housings are specifically designed as a single-round filter housing for low volume liquid filtration. The H-SPF is strongly recommended for use in life science filtration applications, as it meets sanitary requirements and GMP standards. Features include mechanical polishing with a Ra of 15 μin (0.3 μm), easy-to-clean, and thorough drainage which eliminates concerns about remaining liquids. Electro-polishing finish is also an available option. | |||||

| Quality surface finishing | With an internal Ra of 0.38 μm (15 μin.) and external Ra of 0.4 μm (16 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. All electropolishing is also available | |||||

| Enlarged vent and drain with stepped thread connections | Internal diameter connects with 8mm tube. Integrated vent and drain with stepped thread ensure secure tube connetion during drain and vent operations | |||||

Quick-release sectional closure clamp

| Quick disassembly of housing bowl Provides increase pressure endurance by 20% compared to normal clamps Provides perfect sealing for PTFE o-rings with max. operating pressure up to 10 bar (145 psi) | |||||

Adjustable nut on legs

| Allows for filter length to be adjusted | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-GCF Series | ||||||

|---|---|---|---|---|---|---|

| H-GCF Gas Filter Housings are designed for air/gas filtration in biotechnology, chemical, electronic, and food & beverage industries. The housings are compatible with standard cartridges to meet the requirements of air/gas filtration. Endcap design of the housing is Code 7 (external 226 double o-ring with 2 locking tabs) which provides safe and secure sealing. Features include mechanical polishing with a Ra of 15 μin (0.3 μm), easy-to-clean, and thorough drainage which eliminates concerns about remaining liquids. Electro-polishing finish is also an available option. | |||||

| Designed for Code 7 cartridges | Provides safe and secure sealing of cartridges with 226 double o-ring and 2 locking tabs | |||||

| Quality surface finishing | With an internal Ra of 0.38 μm (15 μin.) and external Ra of 0.4 μm (16 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. All electropolishing is also available | |||||

Vent and drain options

| Available with vent and drain options to allow easy clean and thorough drainage | |||||

Standard housing options

| Housing flange connections are designed in accordance with international standards to allow connection to industry-standard connections | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-GCF II Series | ||||||

|---|---|---|---|---|---|---|

| H-GCF Gas Filter Housings are designed for medium and high-pressure air/gas filtration in biotechnology, chemical, electronic, and food & beverage industries. The housings are compatible with standard cartridges to meet the requirements of air/gas filtration. Endcap design of the housing is external 226 double o-ring with 2 locking tabs which provides safe and secure sealing. Features include mechanical polishing with a Ra of 15 μin (0.3 μm), e asy-to-clean, and thorough drainage which eliminates concerns about remaining liquids. Electro-polishing finish is also an available option. | |||||

| Designed for 226 cartridges | Provides safe and secure sealing of cartridges with 226 double o-ring and 2 locking tabs | |||||

| Quality surface finishing | With an internal Ra of 0.38 μm (15 μin.) and external Ra of 0.4 μm (16 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. All electropolishing is also available | |||||

Vent and drain options

| Available with vent and drain options to allow easy clean and thorough drainage | |||||

Standard housing options

| Housing flange connections are designed in accordance with international standards to allow connection to industry-standard connections | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-CPF PTFE Series | ||||||

|---|---|---|---|---|---|---|

| H-CPF PTFE-Lined Filter Housings are designed for use with corrosive fluids (acids & bases) in fine chemical applications. Fluid contact area is composed of PTFE or PFA which solves chemical compatibility issues with stainless steel filter housings, especially for use with aggressive acids. The housings are customizable for flow rate requirements. | |||||

| Fluoropolymer Lined Flow Path | Allows chemical compatibility with acids and bases - corrosive fluids, including Nitric Acid (conc.), Sulfuric Acid (conc.), Sodium Hydroxide (conc.), THF, TFA, and other chemicals | |||||

| Multiple Configurations to Match Flow Requirements | Available in 1, 3, 5, and 7 round configurations, and custom sizes are available. Bowl designs available for 5, 10, 20, 30, and 40- inch filter lengths. | |||||

| High Operating Temperature | With a max. operating temperature of 150°C (302°F), the housings are ideal for use in a wide range of elevated chemical flows. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-CCF Series | ||||||

|---|---|---|---|---|---|---|

| H-CCF Filter Housings feature T-line configuration which allows for easy installation into various tools and locations. The bowl is sanitary grade and has a finished polishing of Ra < 0.38μm (15 μin.) making it suitable for a variety of applications. Since the housing is a compact structure, the top of the filter housing can be supported to rigid pipe. The tri-clamp connection of the housing makes it easy to remove the bowl and replace filter elements. There is no liquid spillover during the replacement process, since the bowl can drop down after release of the tri-clamp. In addition, the drain valve located at the bottom of the filter housing allows for easy drainage. | |||||

| T-line configuration with top inlet and top outlet | T-line configuration allows tubing to be kept inline | |||||

| Tri-clamp bowl connection | No liquid spillover when replacing filter cartridges as bowl can drop down after release of clamp Design allows for safe, easy sealing of bowl to housing head | |||||

| Drain on housing bottom | Easy to drain | |||||

| Quality surface finishing | With an internal bowl Ra of 0.38μm (15 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-CCF Machined Head Series | ||||||

|---|---|---|---|---|---|---|

| H-CCF Filter Housings feature T-line configuration which allows for easy installation into various tools and locations. The bowl is sanitary grade and has a finished polishing of Ra < 0.38μm (15 μin.) making it suitable for a variety of applications. Since the housing is a compact structure, the top of the filter housing can be supported to rigid pipe. The tri-clamp connection of the housing makes it easy to remove the bowl and replace filter elements. There is no liquid spillover during the replacement process, since the bowl can drop down after release of the tri-clamp. In addition, the drain valve located at the bottom of the filter housing allows for easy drainage. | |||||

| T-line configuration with top inlet and top outlet | T-line configuration allows tubing to be kept inline | |||||

| Tri-clamp bowl connection | No liquid spillover when replacing filter cartridges as bowl can drop down after release of clamp Design allows for safe, easy sealing of bowl to housing head | |||||

| Drain on housing bottom | Easy to drain | |||||

| Quality surface finishing | With an internal bowl Ra of 0.8 μm (32 μin.) the sanitary surface finish prevents entrapment or build-up of contaminants | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-SCFII Mini Filter Series | ||||||

|---|---|---|---|---|---|---|

| H-GCF Gas Filter Housings are designed for medium and high-pressure air/gas filtration in biotechnology, chemical, electronic, and food & beverage industries. The housings are compatible with standard cartridges to meet the requirements of air/gas filtration. Endcap design of the housing is external 226 double o-ring with 2 locking tabs which provides safe and secure sealing. Features include mechanical polishing with a Ra of 15 μin (0.3 μm), e asy-to-clean, and thorough drainage which eliminates concerns about remaining liquids. Electro-polishing finish is also an available option. | |||||

| Mirror Polish; Internal Electro-Polished Surfaces | Provides a clean, corrosion-resistant filtration environment for demanding cleanliness applications. | |||||

| Multiple Housing Configurations | Available with inlet/outlet or with inlet/outlet and integrated vent/drain to allow easy installation and retrofit in a variety of locations. | |||||

Quality assurance

| These products are manufactured in a facility which adheres to ISO 9001 Practices. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-SICF Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter H-SICF Filter Housings are designed for use in pre-filtration and clarification processes for beverages, drinking water, fine chemicals, pharmaceutical, and other industrial applications. Constructed of 304 or 316L stainless steel, the housing also ha s a mechanically polished surface finish and can accept filter cartridges with DOE, 222 or 226 end connections, as well as car tridges in 10”, 20”, 30”, or 40” configurations. In addition, it features a swing bolt closure at the top of the filter housing for easy access and installation. Mirror finishing and internal polishing of 0.6m Ra are ensured by mechanically polishing the filter housing 5 to 7 times. | |||||

| Designed for most common cartridges | Provides safe and secure sealing of cartridges with DOE, 222, or 226 connection. | |||||

| Quality surface finishing | With an internal Ra of 0.6 μm (24 μin.) and external Ra of 0.8 μm 32 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

| Vent and drain options | Available with vent and drain options to allow easy clean and thorough drainage. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

S-SIF Series | ||||||

|---|---|---|---|---|---|---|

| Cobetter S-SIF Filtration System Series are specifically designed and engineered for industrial fluid filtration. They contain all the necessary componentsincluding pressure source (pump), filter housings, stainlesssteel pipes, pressure gauge, drain valve, and filtration trolley. The system comesfully assembled, and requiresonly inlet and outlet connections. The system isa multi-stage filtration system and the filter housingscan meet specific requirementsand needs. Cobetter can also provide the filter cartridgesinside the system to meet application requirements. In addition, Cobetter can supply different pressure sources: stainlesssteel water pump, gear pumps, pneumatic pumps, or air diaphragm pumps. Single-round filter housing systemsuse Tri-clamp connections, while other systemsuse flange connections. Design pressure can reach 10 bar (145 psi). | |||||

| Quality surface finishing | Mechanical polished surfaces with sanitary grade and industrial grade polishing available. | |||||

| Multiple Configurations to Match Process Flows | S-SIF I: 3 Stages - meet the needs of fluids that contain a low solid content but require a high filter retention. S-SIF II: 1st Stage Bag Housing Series; 2nd- 3rd Stages. Liquid Filter Housing – meet the needs of fluids with a high solid content. Use of filter bags in the first stage is a more economical method of removing large pore size particles and yields higher filter retention in the latter two stages. S-SIF III: Customized Filtration System | |||||

Economical Supports | Three-leg support bracket configuration make it easy to secure the housing to a flat surface. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

Plastic Cartridge Housing

Cobetter produces plastic housing in PFA, PVDF, PP, and FRB materials to meet the needs of your chemical applications. This can reduce ionic contamination like with the PFA housing or reduce costs with PP housings.

| Product | Housing Material | Configuration | Internal Filter | Applications | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PFA or PTFE | PP | PVDF | FRP | Single Round | 222 | 226 | 334 | HF150 | Liquid | |||||||

| Fluorolink PFA → | • | • | • | • | ||||||||||||

| HCP → | • | • | • | • | • | • | ||||||||||

| 130HCP Resin → | • | • | • | • | ||||||||||||

| H-FRP Filter → | • | • | • | • | ||||||||||||

View Key Features & Benefits by Series | Plastic Cartridge Housing

Fluorolink Series | ||||||

|---|---|---|---|---|---|---|

| Fluorolink™ is an all-fluoropolymer housing designed for ultra-high purity chemicals, chemical blends, and certain agressive chemicals applications. | |||||

Industry standard fittings | Industry standard flared fittings for easy installation | |||||

Compact design | Compact design is space saving and ideal for chemical distribution and on-tool applications | |||||

High temperature rating | Temperature rating to 100°C is ideal for the majority of chemical dispense, clean, and etch processes | |||||

Three locking ring choices | Three locking ring material choices can be matched to chemicals and solvents for robust operation and long life | |||||

Sturdy mounting bracket | Integrated mounting bracket enables secure installation | |||||

Large vents/drains | Larger 1/2” vents and drains promote faster venting and draining to reduce startup and filter changeout times | |||||

Chemical-compatible O-rings | TEV O-ring and Chemraz® options from Banner Industries offer complete range of chemical compatibility and a leak tight seal | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

HCP Series | ||||||

|---|---|---|---|---|---|---|

| HCP Filter Housings are constructed of 100% natural polypropylene or PVDF without any coloring agents or chemicals. These housings provide broad chemical compatibility and are ideally suited for food & beverage, ultrapure water, and other high purity chemical applications. | |||||

100% natural polypropylene (PP) construction or PVDF | Provides cleanliness and broad chemical compatibility Low extractables - no chemicals and colorants are released during filtration process. | |||||

T-line configuration with top inlet and top outlet | inlet and top outletT-line configuration allows tubing to be kept inline | |||||

Drain on housing bottom | Easy to drain | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

130HCP Series | ||||||

|---|---|---|---|---|---|---|

| 130HCP Filter Housings are constructed of 100% natural polypropylene without any coloring agents or chemicals. These housings provide broad chemical compatibility and are ideally suited for food & beverage, ultrapure water, and other high purity chemical applications. | |||||

| 100% natural polypropylene (PP) construction | Provides cleanliness and broad chemical compatibility Low extractables - no chemicals and colorants are released during filtration process. | |||||

T-line configuration with top inlet and top outlet | T-line configuration allows tubing to be kept inline | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-FRP Series | ||||||

|---|---|---|---|---|---|---|

| Cobber H-FRP Series Filter Housings are designed for use with HF150 Series Filter Cartridges and are mainly used for large fluid (liquid/water) flow rate applications, especially in seawater desaliation, water pre-filtration, clarification, fine chemicals, pharmaceutical, and other industrial applications. Designed for large flow rates, this filter housing requires a small area for installation. It is cost efficient and easy to operate when compared to traditional filter housings. The system will be custom designed and manufactured per customer site conditions if flow rates exceed 300 m3/h (1320 gpm). | |||||

| Modular design | Provides easy connection and dissassembly. Easily configured to match process flow and filtration requirements. | |||||

| Valve on branch tube | Allows for individual or multiple filter changeouts while system remains running | |||||

| High flow, efficient footprint, available in horizontal and vertical designs | Provides high flow in space-saving configurations | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

High Flow

High flow housing can be utilized for water applications to reduce the foot print of the area needed for filtration. The large pleated cartridges makes it easier and faster to change out the filter housing and get the process back up and running quickly.

| Product | Housing Material | Configuration | Internal Filter | Applications | ||||

|---|---|---|---|---|---|---|---|---|

| PP | SS | Single Round | 334 | HF150 | Liquid | |||

| 130HCP Resin → | • | • | • | • | ||||

| H-HF150 High Flow Industrial → | • | • | • | • | ||||

View Key Features & Benefits by Series | High Flow

130HCP Series | ||||||

|---|---|---|---|---|---|---|

| 130HCP Filter Housings are constructed of 100% natural polypropylene without any coloring agents or chemicals. These housings provide broad chemical compatibility and are ideally suited for food & beverage, ultrapure water, and other high purity chemical applications. | |||||

| 100% natural polypropylene (PP) construction | Provides cleanliness and broad chemical compatibility Low extractables - no chemicals and colorants are released during filtration process. | |||||

T-line configuration with top inlet and top outlet | T-line configuration allows tubing to be kept inline | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

H-HF150 Series | ||||||

|---|---|---|---|---|---|---|

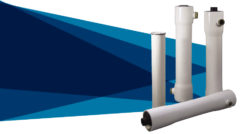

| Cobetter H-HF150 Series Industrial Filter Housings are designed for use with HF150 Series Filter Cartridges and are mainly used for large fluid (liquid/water) flow rate applications, especially in water treatment, beverages, fine chemicals, pharmaceutical, and other industrial applications. Designed for large flow rates, this filter housing requires a small area for installation. It is cost efficient and easy to operate when compared to traditional filter housings and is available in 304 or 316L stainless steel, which ensures strong corrosion resistance for a wide range of applications. In addition, the H-HF150 is available in both horizontal and vertical configurations. Normally, a vertical configuration is composed of 10 round 40” filters. For flow rates over 1000 m3/h (4400 gpm), we recommend choosing a horizontal configuration with 60” HF150 filter cartridges as it satisfies large flow rate applications and is relatively easy to change. | |||||

| High flow, efficient footprint | Provides high flow in space-saving configurations | |||||

| Quality surface finishing | With an internal Ra of 0.6 μm (24 μin.) and external Ra of 0.8 μm 32 μin), the sanitary surface finish prevents entrapment or build-up of contaminants. | |||||

| Vent and drain options | Available with vent and drain options to allow easy clean and thorough drainage. | |||||

Specs, Flow Curves, and Part Number Configurator → | ||||||

FILTERS BY INDUSTRY

NEED HELP?

We have a team of filtration experts that can help with all of your filtration needs. If you’re not sure what you’re looking for, fill out this request form or contact us here and one of our team members will be in touch with product recommendations.

ORDER ONLINE

We have a selection of filtration products on our e-commerce website, but there are many more options available. If you’re looking for something specific, tell us about it here.